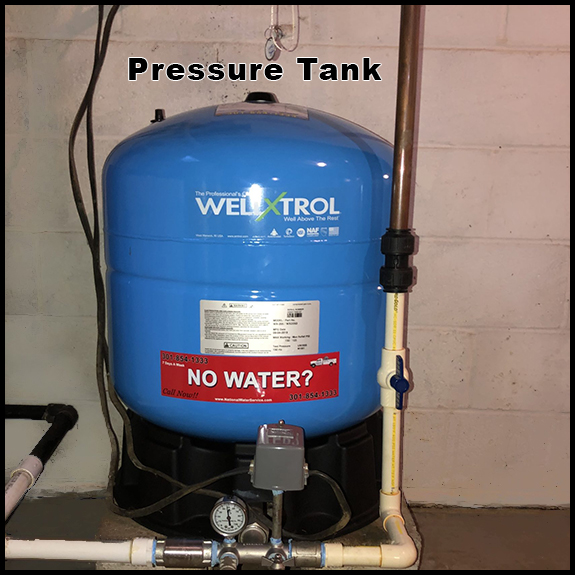

Your pressure tank is the “brain” of your well system. It controls when your pump turns on and protects your motor from premature failure. Whether you need a heavy-duty Steel Pressure Tank or a corrosion-proof Composite Tank, we provide expert installation to keep your water flowing.

Expert Well Pressure Tank Install & Replacement in Maryland, Virginia, and DC since 1979.

A well pressure tank serves two critical purposes: it stores pressurized water so your pump doesn’t have to turn on every time you flush a toilet, and it provides “drawdown” to protect your pump motor.

Without a properly functioning tank, your well pump would “short-cycle”—turning on and off every few seconds. This is the #1 cause of burned-out submersible pumps. Investing in a quality well water pressure tank installation is the best way to extend the life of your entire well system.

Pressure tanks usually fail when the internal air bladder ruptures. Because the tank becomes “waterlogged,” it loses its ability to regulate pressure. Watch for these red flags:

Pulsing Water Pressure: Your shower water feels like it is “surging” or pulsing rhythmically.

Rapid Clicking: You hear the pressure switch clicking on and off rapidly in your basement or utility room.

Sudden Pump Failure: If your pump suddenly stops working, the pressure tank is often the underlying cause.

High Electric Bills: A short-cycling pump uses significantly more electricity than a healthy system.

Every well environment is different. We offer the two industry-standard options to ensure your system lasts:

| Feature | Steel Tanks (Well-X-Trol) | Composite Tanks (Flexcon) |

|---|---|---|

| Best For | Basements / Standard Use | Damp Crawlspaces / Acidic Water |

| Corrosion Risk | Low (Powder Coated) | Zero (Rust-Proof) |

| Warranty | 7-Year Total Warranty | Lifetime Options Available |

The traditional choice for durability. Our steel tanks (like Well-X-Trol) feature a high-grade butyl diaphragm and a powder-coated exterior to resist the humidity of a basement or utility room. They are the “gold standard” for strength and longevity.

Ideal for aggressive or acidic water conditions. Because they are made of a high-density polyethylene inner shell wrapped in fiberglass, they cannot rust or corrode. These tanks are lightweight, extremely durable, and perfect for damp locations where a steel tank might rust on the outside.

Replacing a pressure tank involves more than just plumbing. It requires precise air-pressure calibration to match your pump’s “cut-in” pressure.

System Diagnosis: We test the air charge and the pressure switch to confirm if the tank is truly failed.

Removal & Disposal: We drain and haul away your old, heavy, waterlogged tank.

The Install: We install the new tank using high-quality brass “tank tees” and new pressure gauges to ensure a leak-free system.

Calibration: We pre-charge the tank to exactly 2 PSI below your pump’s cut-in pressure (typically 38 PSI for a 40/60 system) for perfect performance.

Complete System Diagnostic: We don’t just swap parts; we find the root cause.

High-Quality Brass Tank Tee: We replace the critical connection points that often corrode.

New Pressure Gauge & Switch: Ensuring your pump knows exactly when to kick in.

Professional Air Pre-Charge: Every tank is calibrated to 2 PSI below your specific pump’s cut-in.

Haul Away: We dispose of your old, heavy, waterlogged tank so you don’t have to.

You cannot simply swap one tank for another without checking the math. A professional well pressure tank installation requires matching the tank’s “drawdown” capacity to your pump’s Gallons Per Minute (GPM) output.

Minimum Run Time: We size tanks to ensure your pump runs for at least one full minute per cycle to keep the motor cool.

Calibration: We pre-charge every tank to exactly 2 PSI below your pump’s “cut-in” pressure for optimal performance.

Premium Brands: We exclusively install Well-X-Trol, Well Rite and Flexcon—the most reliable tanks on the market.

One of the most frequent questions we receive is, “How much does it cost to replace a well pressure tank?” While every home is unique, the total investment typically depends on three main factors:

Tank Capacity & Size: A standard residential tank (usually 32 to 44 gallons of drawdown) costs less than the larger 80 or 119-gallon tanks required for high-demand homes or deeper wells.

Material Choice (Steel vs. Composite):

Steel Tanks: Generally the most cost-effective and traditional option.

Composite Tanks: Often carry a slightly higher upfront cost due to their corrosion-proof fiberglass construction and extended durability in harsh environments.

System Components: A professional replacement includes more than just the tank. We often replace the pressure switch, pressure gauge, and tank tee at the same time to ensure the entire control system is new and reliable.

Our Warranty Promise: We only install professional-grade tanks from Well-X-Trol, Well Rite and Flexcon. These tanks are built to higher standards than “big box” store models and come backed by industry-leading manufacturer warranties and our National Water Service labor guarantee.

A waterlogged tank is full of water instead of air. To check:

The “Knock” Test: Tap the top of the tank. It should sound hollow (full of air). If it makes a dull “thud” from top to bottom, it’s likely waterlogged.

The “Weight” Test: A healthy tank is light when empty. A failed tank with a ruptured bladder stays heavy and full of water even when the system is drained.

The Valve Test: Briefly press the air valve (Schrader valve) at the top. If water squirts out instead of air, the internal bladder is definitely ruptured and the tank needs replacement.

If your faucets are gurgling or spitting bursts of air, it often means your pressure tank’s air bladder has failed or your pump is drawing in air. This puts massive strain on your plumbing and should be inspected immediately to prevent a pipe burst.

In Maryland and Virginia, where utility rooms and basements can be damp, Composite Pressure Tanks are a fantastic investment. They never rust, they are lighter (easier to install in tight spaces), and they typically outlast steel tanks in high-humidity environments. If your current steel tank has rust on the bottom, a composite tank is the perfect permanent solution.

That clicking is the sound of your pump motor starting and stopping too fast (short-cycling). Ignoring it for even a few days can overheat the motor and turn a simple Pressure Tank Replacement into a much more expensive Submersible Pump Replacement.

You can, but it is risky. The air pressure must be set exactly 2 PSI below your pump’s “cut-in” pressure while the tank is completely empty of water. If the ratio is wrong, your pump will cycle too often or you’ll experience “dead spots” where no water flows at all.

A standard well pressure tank replacement typically takes 2–4 hours. This includes draining the old system, installing the new tank and hardware, and calibrating the pressure switch for optimal performance.

Yes. 5–7 year manufacturer warranties on brands like Well-X-Trol and Flexcon.

With over 47+ years of experience in water repair and management, we are proud to offer dedicated Water Techs & Master Plumbers to homes and businesses. Get affordable pricing, competitive quotes, and quality materials that last.